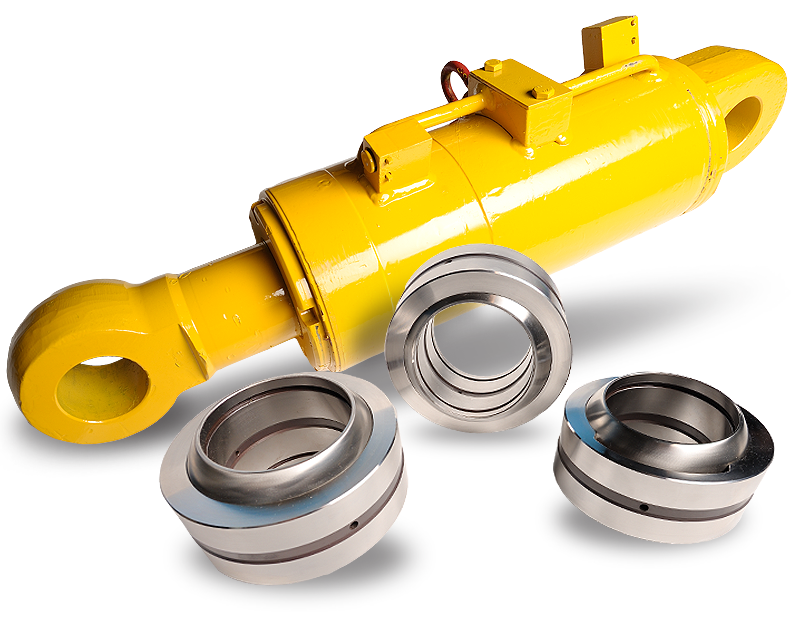

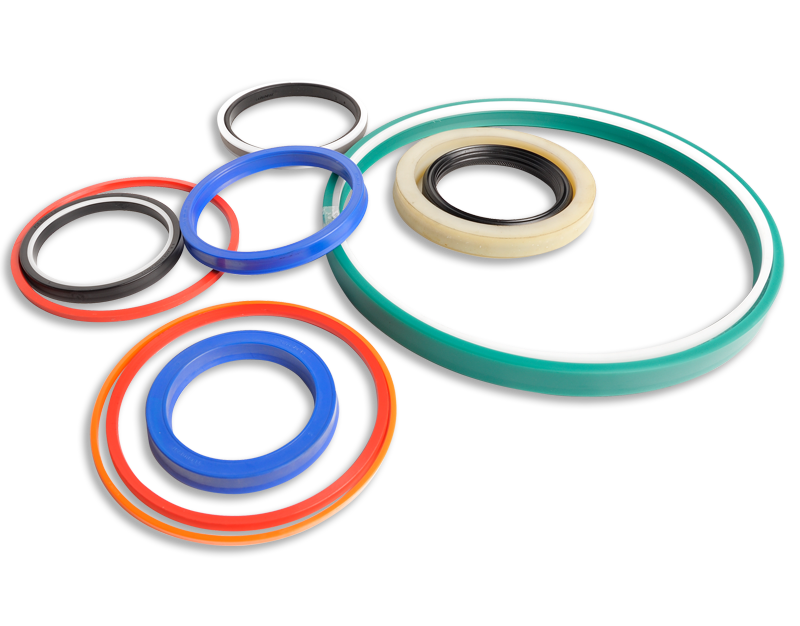

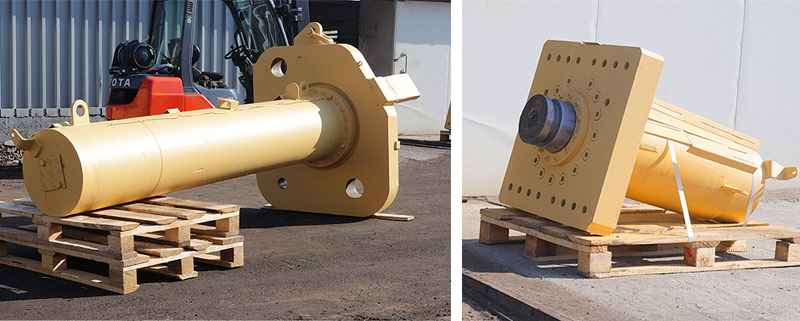

The main profile of our business comprises manufacture and repairs of hydraulic systems. Our offer includes cylinders for mining machinery, longwall supports, construction machinery, and all types of processing lines where hydraulic cylinders are used.

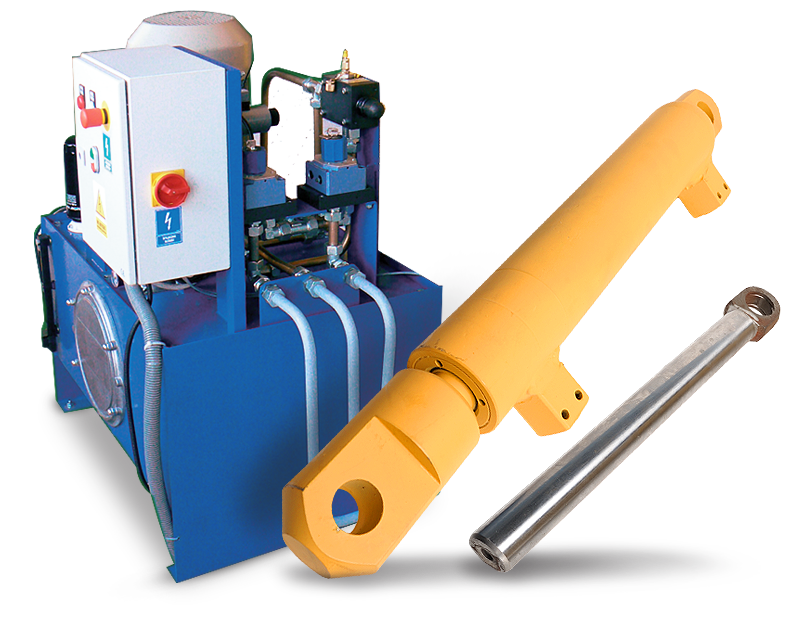

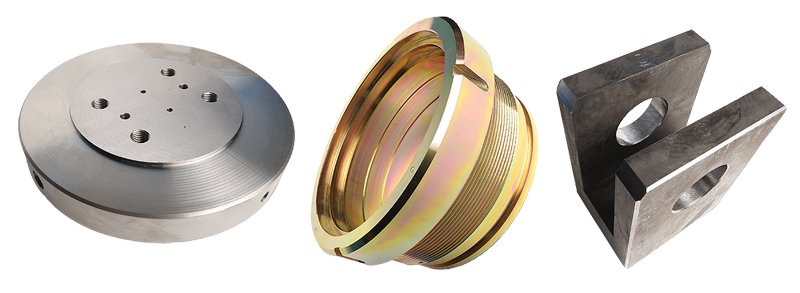

We offer manufacturing and repairing of single- and multi-stage cylinders, with dimensions up to Ø 400. The technology of cylinders regeneration and manufacture comprises coating galvanically the cylinder and piston rod with two layers of technical chromium or inert gas pad welding with a chromium-nickel wire. Each cylinder is controlled for tightness on a pressure test station.

We have the stock of machinery including numerically controlled machines, such as: Vertical Machining Centre WMC 1100 made by WAGNER and MCFV 1060 made by TAJMAC, lathes with power tools TUR 560 made by HACO and TAE-45 made by AFM DEFUM.

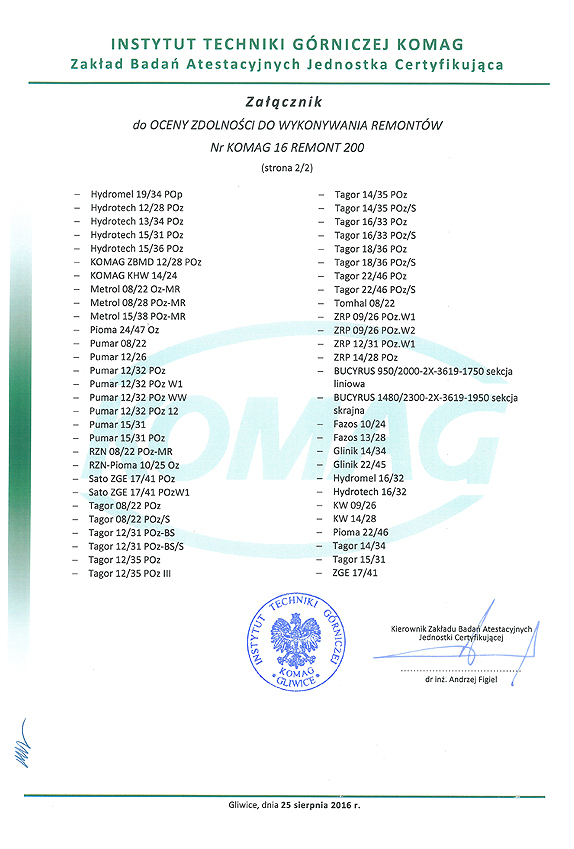

We perform all the work based on our own or the Client’s technical documentation. We have certificates for repair work performance issued by the KOMAG Institute of Mining Technology.